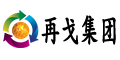

☆ Scrap steel processing flow chart

Scrap Iron and steel scrap crushing production line is an advanced equipment in renewable resources industry, mainly used for the processing of scrap steel lightweight material such as waste car body, tin plates, household appliances, bicycle, empty cans etc. make them into the top-level steel-making raw materials. By continuously crushing, it removes the coating of the materials, increasing their volume density and increases their dissolution rate under a certain shape. The production line uses electricity as driving source, by of the principle of hammer struck, the hammers on the main rotor is driven by high speed, high torque and high voltage motor, the hammers hit materials to be broken in turn, through the space formed between the lining and the hammer, the scrap steel and iron will be torn into pieces that meet specifications, and with the effect of magnetic device, we can get new steelmaking furnace of high purity and quality.

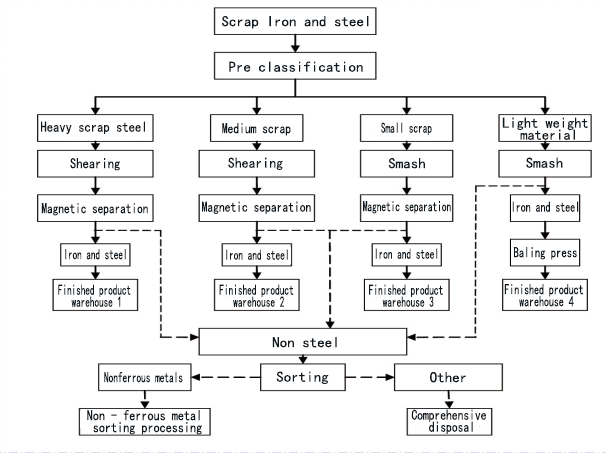

☆ Flow chart of scrap iron and steel crushing production line

The company has purchased advanced crushing production line of scrap iron and steel , through mechanical processing, thin material of scrap steel can be turned into new steel-making furnace, a product of high density, small size, less impurities and high tapping rate with reduced pollutant emission during smelting process to achieve energy-saving and emission reduction. The Scrap steel products are sold to major steel enterprises in North china.

☆ Scrap steel crushing line put into use

The growth of scrap steel consumption reflects the change of raw material structure of key steel-making enterprises, and is very beneficial to the recycling of renewable resources, energy saving, emission reduction, and improvement of the ecological environment. In 2016, China's recycling volume of scrap iron and steel was 151 million 300 thousand tons, an year-on-year increase of 5.2%. Among which the key large steel-making enterprises recycled 90 million 100 thousand tons of scrap iron and steel, an year-on-year increase of 8.2%, maintaining growth trend throughout the year.

☆ Iron and steel scrap processing, thin material

The single comprehensive consumption of scrap steel during steel-making is 111 kg / ton of steel, an year-on-year increase of 7 kg / ton. The growth of scrap steel consumption reflects the change of raw material structure of key steel-making enterprises, which is very beneficial to the recycling of renewable resources, energy saving, emission reduction, and improvement of the ecological environment. The steel production of the Beijing Tianjin Hebei region accounted for 40% of total production nationwide, abundant resource of scrap iron and steel, the scrap iron and steel consumption of steel-making enterprises continued to increase. In 2017, the single comprehensive consumption of scrap steel reached 150 kg / ton, providing a good market prospects for the development of scrap iron and steel recycling industry.

☆ Products after the processing of scrap steel crushing line

The advantages of the products after the processing of scrap steel crushing line:

①Density increased. Making the scrap steel thin material into small lumps after crushing.

②The volume reduced. Easier for transportation, waste turned into treasure, protect the environment.

③Slag cleaning. After Smashing, the impurities were removed to improve the quality of the steel.

④When the crushed scrap steel is mixed with other scrap steel, it can fill the gap and increase the feeding density.

⑤During smelting, the feeding times are reduced, saved a lot of labor.

⑥During The smelting, the materials are uniformly heated in the furnace, air pollution is reduced, the operation is easy and simple.

⑦The power consumption per ton of molten steel is lower, crushed scrap iron and steel can be sold by high prices.